Foam Insert Protection Tailor Made for Your Product

Foam Insert Protection Tailor Made for Your Product

Pack4 offers custom foam fabrication for packaging that protects your customer-specific parts and equipment during shipping, moving and storage. Our expert services include design and engineering, die cutting, laminating, sheeting, and assembly. We provide high-performing and long-lasting packaging solutions that meet your budget and keep your products well-protected.

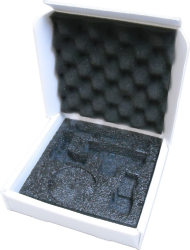

CUSTOM FOAM INSERTS

Custom foam inserts are highly protective and economical, so they are a great way to ship products in either a custom or stock container. They provide insulation against extreme temperatures and shock absorption to protect against vibrations and impact from drops and falls. Foam inserts can be designed, cut, and fabricated to hold any shape and fit into any cavity. In addition to protecting your product, they can also keep individual components organized with custom cavities for each element.

Choosing the right CUSTOM FOAM INSERTS

Custom foam inserts can be fabricated from a variety of materials, with the most common being polyethylene and polyurethane foam.

Polyurethane foam is a soft, lightweight, open-cell material that is highly shock absorbent.

- Ideal for cushioning and protecting delicate items

- Good for items sensitive to vibration

- Elastic qualities allow it to recover its shape quickly

- Can be easily die cut into custom shapes

- Available in a variety of densities and colors

Polyethylene foam is a lightweight and durable closed-cell material that is both shock absorbent and moisture resistant.

- Ideal for protecting heavier items like furniture and appliances that require higher durability

- Moisture and chemical resistant

- Good for vibration dampening and shock absorption

- Can be easily die cut into custom shapes

Choosing the right material for your custom packaging solution depends on several factors. Our experienced design and engineering team will consult with you and conduct a thorough review of your product and the level of protection needed. Some of the factors that influence the material and design of your custom foam packaging solution include:

- Product size and weight

- Fragility

- Shipping and storage environments

- Display requirements

Once the material has been determined, we’ll use state-of-the art CAD software to design and prototype an optimal foam packaging solution that satisfies both your protection needs and your budget. Our diverse manufacturing techniques – die cut, saw cut, water jet cut and hand cut – enable us to produce superior custom and complex packaging for any product.

Common Applications for Custom Foam Fabrication for Packaging

Medical devices & products Food products

Electrical components Electronics

Furniture Consumer products

Industrial equipment Pharmaceuticals

Windows Military equipment

Firearms Wine & liquor

Why Choose Pack4?

Pack4 is a leader in protective packaging with satisfied customers across the United States, Puerto Rico, and the Dominican Republic. We have deep expertise in designing and fabricating custom foam inserts from a variety of materials for a wide range of products. We pride ourselves on delivering high quality packaging solutions with short lead times. Contact us for a consultation about your custom packaging needs.

Pack4 fabricates many types of foam into custom packaging for customer-specific parts and equipment. Our services include design and engineering, die cutting, laminating, sheeting and assembly. We focus on reducing material and labor costs, while making certain our customers’ products are well-protected.

- Polyethylene, polyurethane and specialty foams

- Foam design and engineering

- Die cutting, laminating, sheeting and assembly

Custom foam inserts are highly protective and economical, so they are a great way to ship products in a custom or stock carton. Whether die cut, saw cut, water jet cut or hand cut, we can produce even the most complex inner packaging to protect your product. Our design and engineering team is trained on state of the art CAD software to create the optimal foam packaging solution for your product.